Australia Xinhai Mining Services Pty Ltd

Australia Xinhai Mining Services Pty Ltd

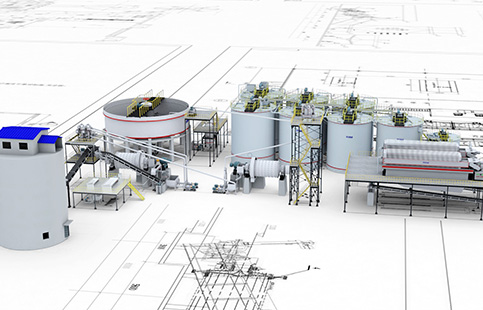

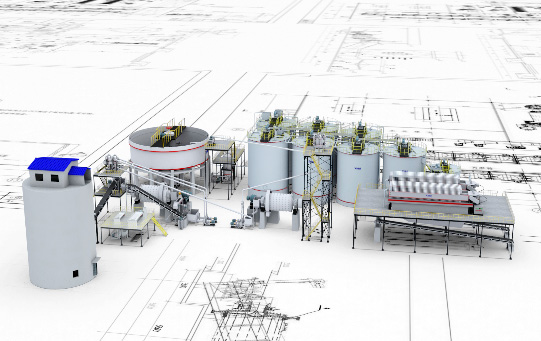

From a single blueprint to stable production, Xinhai ensures seamless integration across design, equipment supply, construction, and commissioning. Every stage is interconnected and fully controllable, enabling faster and more reliable achievement of production standards and targets.

Process flows are tailored to the specific ore properties to ensure both recovery efficiency and economic viability.

Lab-scale test

Pilot-scale test

Xinhai Mine Design Institute possesses extensive experience in mine design, having completed more than 600 projects across a wide range of terrains. These projects vary in scale from several hundred tonnes to several million tonnes per year.

Self-manufactured core equipment and carefully selected auxiliary components ensure precise matching across the entire production process.

Xinhai manufactures over 1,000 types of mining, processing, and metallurgical equipment, supplying complete sets for mines up to 50,000t/d, including large machinery like ball mills under 7 meters in diameter. Leveraging its experience in mine equipment procurement and construction management, along with the advantages of its EPC brand and platform, Xinhai has established a comprehensive procurement and supplier management system. Through rigorous evaluation and selection, Xinhai forms long-term partnerships with excellent suppliers to enhance procurement efficiency and ensure equipment quality. Meanwhile, the company has developed a strict procurement quality management system to achieve standardized management, supporting mining equipment procurement and construction management effectively.

Xinhai has a strict quality management system ensuring all production and procurement follow the quality manual. Project schedules are closely monitored to meet quality standards, while continuous innovation improves product quality.

Xinhai also runs an advanced packaging and shipping system, capable of handling shipment volumes in the hundreds of millions. Its state-of-the-art packaging and shipping center adopts digital and scientific management methods, using ERP and WMS systems for digital and visualized management.

Coordinated construction of the processing plant and tailings system eliminates the issue of “fast front-end, slow back-end.” Installation and commissioning are carried out by Xinhai’s in-house team in a streamlined process, ensuring construction precision, shortening the commissioning period, and enabling rapid achievement of production standards and targets.

Earthwork: Includes site leveling, foundation probing, earth excavation, and backfilling. Foundation probing is conducted by hammer-driving steel rods to assess soil structure and bearing capacity.

Concrete Works: Cover foundational structures such as workshops and equipment foundations, as well as concrete structures including frame-structured power distribution rooms and shear wall-type fine ore bins.

Masonry Works: Include structures such as boundary walls built with red bricks or concrete blocks—any part constructed using masonry techniques falls under this category.

Auxiliary Construction: Includes fully decorated office buildings, living quarters, maintenance workshops, warehouses, water tanks, fences, firefighting systems, sewage pipelines, security facilities, water supply systems, roads, drainage ditches, fueling stations, power supply systems, chemical and test laboratories.

Xinhai has multiple specialized installation and commissioning teams that operate year-round both domestically and internationally. With extensive practical experience, the company has strong capabilities to undertake more than 25 installation and commissioning projects simultaneously.

Xinhai’s installation and commissioning teams are involved in all stages of mine EPC projects—from mineral processing tests, process design, equipment selection, plant design to equipment customization and installation, and process commissioning. All team members understand real project conditions and work together to ensure smooth execution.

At the final stage of installation and commissioning for each project, Xinhai provides on-site training for the client’s staff on operation, inspection and maintenance procedures, and emergency response to ensure successful project handover.

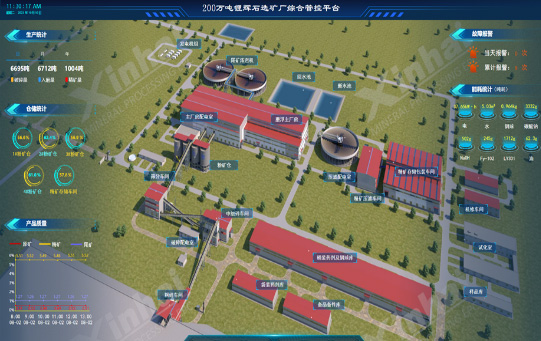

Xinhai's core commissioning services are led by a team of experts from the Xinhai Mining Design Institute, who have extensive experience in mining design. They have a deep understanding of the essence of project design, ensuring that the processing plant is accurately implemented from blueprint to production. The commissioning team optimizes and fine-tunes the process flow, equipment parameters, and interconnectivity based on your actual operating conditions and requirements, significantly reducing commissioning risks and break-in period costs, ensuring efficient and stable equipment operation, and accurately achieving design targets. You can focus solely on overall operations and enjoy the benefits of stable, compliant production outcomes.

Comprehensive management across the entire process, including design, manufacturing, procurement, construction, personnel, and quality.

Based on client requirements, we provide comprehensive management services throughout the entire EPC project implementation process. This includes integrated services such as design management for mining, mineral processing, and tailings storage facilities; equipment manufacturing and procurement management; engineering construction, installation, and commissioning management; as well as project trial operation management.

Efficient and well-organized mine construction management not only effectively ensures the project schedule and quality but also serves as a crucial guarantee for investment and returns!

Continuous technical support after production startup ensures stable and sustained production capacity.